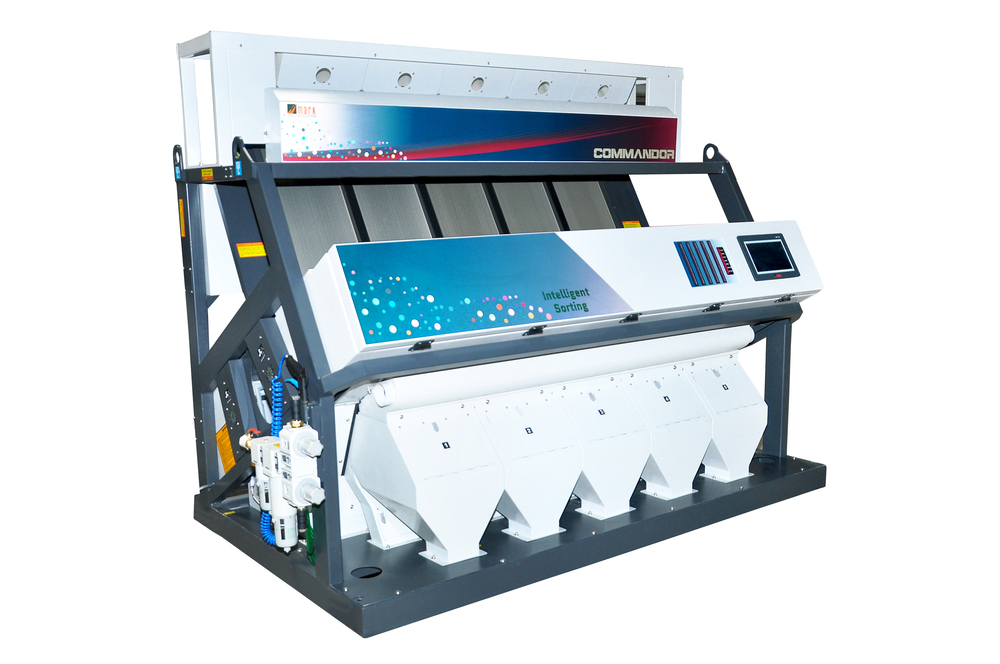

Groundnut Color Sorting Machine

Groundnut Color Sorting Machine

"Welcome to Our Mark Groundnut Color Sorter Machine"

Are you looking to take your groundnut processing to the next level? Look no further! Our cutting-edge Groundnut Color Sorter Machine is here to transform your operations and ensure top-notch quality in every batch.

Why Choose Our Mark Groundnut Color Sorter?

Precision Sorting: Our machine employs state-of-the-art optical sorting technology to meticulously inspect each groundnut and eliminate defects, foreign materials, and discolored nuts. You'll get consistent, high-quality results every time.

Increased Productivity: Say goodbye to manual sorting and hello to increased productivity. Our color sorter can process groundnuts at lightning speed, reducing labor costs and boosting efficiency.

Quality Assurance: With our machine, you can guarantee that only the finest groundnuts make it to the market. This means higher market value and a competitive edge in the industry.

Customizable Solutions: We understand that every processing plant is unique. That's why our color sorter machine can be tailored to meet your specific requirements, ensuring seamless integration into your existing setup.

Key Features:

- Advanced Color Recognition: Accurately separates groundnuts based on color and shape.

- User-Friendly Interface: Easy-to-use controls for operators of all skill levels.

- Low Maintenance: Designed for durability and minimal downtime.

- Cost-Effective: Reduce waste and optimize your production process.

Groundnut Color Sorter Machine:

- High Speed HD camera, Ultra HD imaging & analysis technology, high-speed processing, Accurate Identification.

- Intelligent image processing.

- AI-Deep learning technology.

- Intelligent study data classification.

- 5400 x 3 pixel RGB sensor.

- Image can taken 122 million pixels per second, Easy to use interface.

- High level AI deep learning technology, user friendly interface, easy operation.

- Multi-function, Multi-purpose, widely used for all kind of rice, grain, nuts, plastics etc.

- High and specification ensure high stability with high sorting accuracy.

- Even light system, 1.2 Billion life cycle.

- Accurate dimming control valve.

- High speed matrix valve, Maintenance free SMPS.

- Mark brand full HD colorful 10.1 touch screen.

- Customer friendly user interface. Linux based operating systems.

- Powerful communication system feeder.

- Closed loop sensor based feeder systems self calibration. Material even feeding system LED.

- Micro controlled LED high reliability and long lifespan LED light resources smart cooling.

- 16 Million colors RGB background LED realtime background color adjustmentable.

- Combined with color sorting, AI sorting sort difficult impurities like micro color difference.

- FPGAs based best-in-class signal processing capabilities for high bandwidth applications, Built on the 28nm HPL Processor! HD lens for clear imaging HM.

| Chute Option Available | 10 Chute | 8 Chute | 7 Chute | 6 Chute | 5 Chute | 4 Chute | 3 Chute | 2 Chute | 1 Chute | 1 Chute 32 Channel |

| Chute Distribution (P+S+F) | 6+2+2 (or) 6+2+1+1 | 5 + 2 + 1 | 4+2+1 | 4+1+1 | 3+1+1 | 2+1+1 | 2+1 | 1+1 | 1 | 1 |

| Output (TPH) for Rice/Dal | 6 to 8 | 5 to 7 | 4 to 6 | 3.5 to 5.5 | 3 to 5 | 2 to 4 | 1.5 to 2.5 | 1 to 2 | 0.75 to 1.5 | 0.500 to 1.0 |

| No. of Camera (F&R) | 10 + 10 | 8+8 | 7+7 | 6+6 | 5+5 | 4+4 | 3+3 | 2 + 2 | 1 + 1 | 1 + 1 |

| Air Requirement @7.5/cm2 | 180 CFM | 150 CFM | 132 CFM | 113 CFM | 96 CFM | 72 CFM | 54 CFM | 38 CFM | 28 CFM | 15 CFM |

| Compressor Requirement | 40 HP Screw | 30 to 40 HP Screw | 30 HP Screw | 25 HP Screw | 25 HP Screw | 20 HP Screw | 15 HP Screw | 10 HP Screw | 7.5 HP Screw | 5 HP Screw |

| Dimension (LxWxH)Feet | 13.83x 4.88x5.97 | 10.87x 4.88x5.97 | 9.73x 4.88x5.97 | 8.59x 4.88x5.97 | 7.46x 4.88x5.97 | 6.33x 4.88x5.97 | 5.19x 4.88x5.97 | 4.1x 4.88x5.97 | 2.92x 4.88x5.97 | 1.94x 4.16x4.76 |

| Cabin Dimension (LxWxH)Feet | 18x10x8 | 16x10x8 | 14x10x8 | 13x10x8 | 12x10x8 | 10x10x8 | 9x10x8 | 8x10x8 | 7x10x8 | Movable type with wheel |

Enquiry