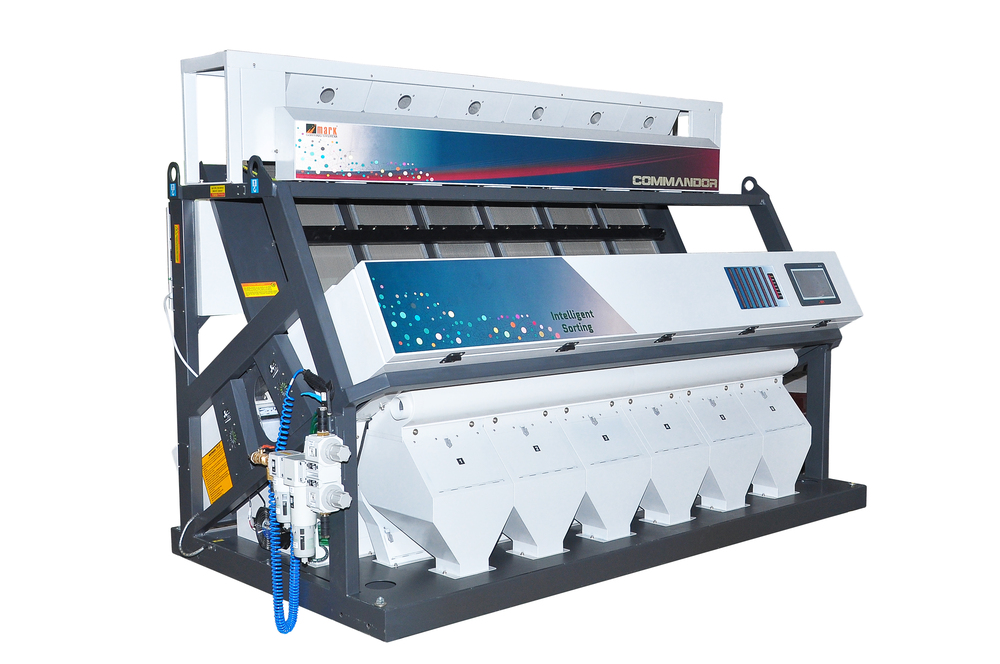

Dal Color Sorting Machine

Dal Color Sorting Machine

A dal color sorting machine, also known as a lentil color sorting machine or pulse color sorter machine, is a specialized piece of equipment used in the food processing industry to sort and separate lentils, pulses, and other similar food products based on their color and quality.

Mark Dal Color Sorter Machine Features:

- High Speed HD camera, Ultra HD imaging & analysis technology, high-speed processing, Accurate Identification.

- Intelligent image processing.

- AI-Deep learning technology.

- Intelligent study data classification.

- 5400 x 3 pixel RGB sensor.

- Image can taken 122 million pixels per second, Easy to use interface.

- High level AI deep learning technology, user friendly interface, easy operation.

- Multi-function, Multi-purpose, widely used for all kind of rice, grain, nuts, plastics etc.

- High and specification ensure high stability with high sorting accuracy.

- Even light system, 1.2 Billion life cycle.

- Accurate dimming control valve.

- High speed matrix valve, Maintenance free SMPS.

- Mark brand full HD colorful 10.1 touch screen.

- Customer friendly user interface. Linux based operating systems.

- Powerful communication system feeder.

- Closed loop sensor based feeder systems self calibration. Material even feeding system LED.

- Micro controlled LED high reliability and long lifespan LED light resources smart cooling.

- 16 Million colors RGB background LED realtime background color adjustmentable.

- Combined with color sorting, AI sorting sort difficult impurities like micro color difference.

- FPGAs based best-in-class signal processing capabilities for high bandwidth applications, Built on the 28nm HPL Processor! HD lens for clear imaging HM.

| Chute Option Available | 10 Chute | 8 Chute | 7 Chute | 6 Chute | 5 Chute | 4 Chute | 3 Chute | 2 Chute | 1 Chute | 1 Chute 32 Channel |

| Chute Distribution (P+S+F) | 6+2+2 (or) 6+2+1+1 | 5 + 2 + 1 | 4+2+1 | 4+1+1 | 3+1+1 | 2+1+1 | 2+1 | 1+1 | 1 | 1 |

| Output (TPH) for Rice/Dal | 6 to 8 | 5 to 7 | 4 to 6 | 3.5 to 5.5 | 3 to 5 | 2 to 4 | 1.5 to 2.5 | 1 to 2 | 0.75 to 1.5 | 0.500 to 1.0 |

| No. of Camera (F&R) | 10 + 10 | 8+8 | 7+7 | 6+6 | 5+5 | 4+4 | 3+3 | 2 + 2 | 1 + 1 | 1 + 1 |

| Air Requirement @7.5/cm2 | 180 CFM | 150 CFM | 132 CFM | 113 CFM | 96 CFM | 72 CFM | 54 CFM | 38 CFM | 28 CFM | 15 CFM |

| Compressor Requirement | 40 HP Screw | 30 to 40 HP Screw | 30 HP Screw | 25 HP Screw | 25 HP Screw | 20 HP Screw | 15 HP Screw | 10 HP Screw | 7.5 HP Screw | 5 HP Screw |

| Dimension (LxWxH)Feet | 13.83x 4.88x5.97 | 10.87x 4.88x5.97 | 9.73x 4.88x5.97 | 8.59x 4.88x5.97 | 7.46x 4.88x5.97 | 6.33x 4.88x5.97 | 5.19x 4.88x5.97 | 4.1x 4.88x5.97 | 2.92x 4.88x5.97 | 1.94x 4.16x4.76 |

| Cabin Dimension (LxWxH)Feet | 18x10x8 | 16x10x8 | 14x10x8 | 13x10x8 | 12x10x8 | 10x10x8 | 9x10x8 | 8x10x8 | 7x10x8 | Movable type with wheel |

Enquiry